MingfaTech LED thermal solutions present a perfect solution to this issue. The company has introduced a "star-pin fin-passive cooler" design that utilizes various passive cooling methods to dissipate heat efficiently. In this article, we will discuss MingfaTech LED thermal solutions' LED heat dissipation design in five ways.

1. Pin Fin Heat Sink Design

The pin fin heat sink design is a traditional technique used to dissipate the heat generated by LED lights. It is a cost-effective and easy-to-install design that is widely used in LED applications. MingfaTech LED thermal solutions use a pin fin heat sink design to dissipate heat from LEDs quickly and efficiently. This technique uses a number of thin pins to enhance the surface area, which facilitates easy heat transfer.

2. Star Fin Heat Sink Design

The Star Fin heat sink design is a variation of the pin fin design. It features a more complex structure that enables efficient heat dissipation. This design consists of multiple fins connected to a common base. The fins have a star-shaped cross-section, which increases the surface area and enhances the cooling performance. The Star Fin design is commonly used in high-power LED lighting applications, and MingfaTech LED thermal solutions use this design to dissipate heat from LED lights.

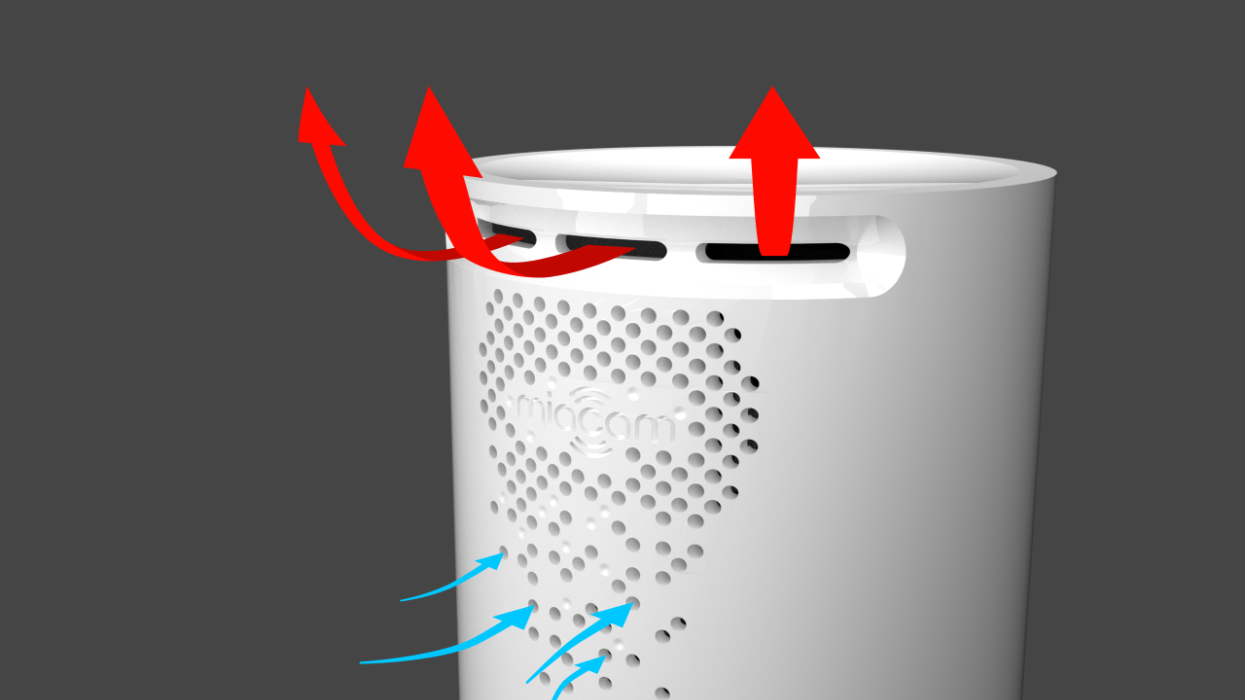

3. Passive Cooling

Passive cooling is another technique used by MingfaTech LED thermal solutions to dissipate heat from LEDs. This technique involves using natural convection and radiation to transfer heat away from the LED chips. Passive cooling is a low-cost and energy-efficient technique that does not require any external power source like fans or pumps. MingfaTech LED thermal solutions use passive cooling techniques in their LED heat dissipation design to ensure efficient heat dissipation.

4. Digger Fin Type

The Digger Fin Type heat sink design is a more advanced cooling solution that features a unique structure. This design features a combination of vertical and horizontal fins that resemble a set of teeth. This unique structure increases the heat transfer surface area and enhances cooling performance. The Digger Fin Type design is commonly used in high-power LED lighting applications, and MingfaTech LED thermal solutions use this design in their LED heat dissipation hardware.

5. Water Oil Cooler

The Water Oil Cooler is an advanced LED heat dissipation technique used by MingfaTech LED thermal solutions. This system is a combination of water and oil that flows through the cooling system, dissipating heat from the LEDs. The water oil cooler technique is commonly used in high-power LED lighting applications, where passive cooling techniques cannot achieve efficient cooling. MingfaTech LED thermal solutions use the Water Oil Cooler method in their LED heat dissipation design to ensure maximum cooling performance.

In conclusion, MingfaTech LED thermal solutions' LED heat dissipation design in five ways is a comprehensive approach to cool LEDs effectively. The company utilizes different passive cooling techniques like Pin Fin, Star Fin, Digger Fin Type, and Water Oil Cooler to promote energy efficiency, reduce maintenance costs, and increase LED longevity. With the increased usage of LEDs, it is vital to have efficient cooling solutions like these that can ensure optimal performance and longevity of the LEDs.